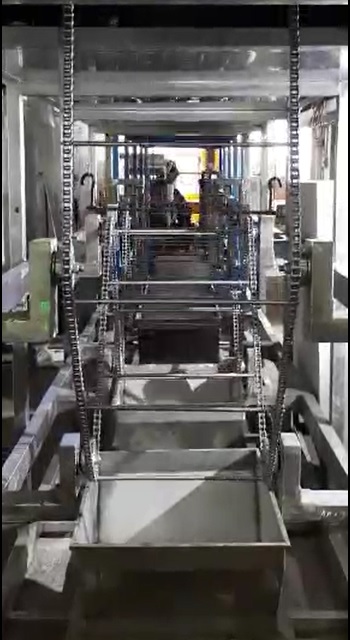

CHAIN CONVEYOR

These types of conveyors are highly suitable when the production requires horizontal

transport between case packers, cartons, in-case fillers, shrink/stretch wrappers or bulk.

packers.

Modular Flex conveyors can flex in all directions resulting in many applications

possibilities Straight and curved sections can be combined into a single system and increase

production efficiency. Elevate, accumulate, distribute, divert, flip, turn or push the products,

we can easily do it by using our flex conveyors.